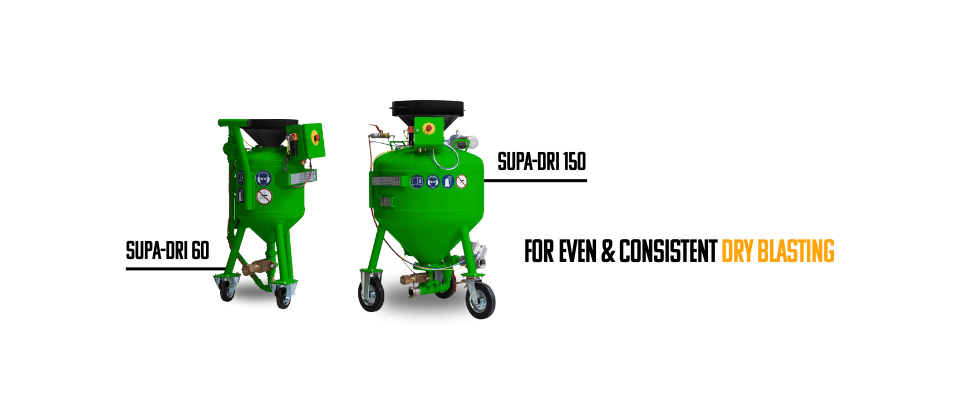

We’re excited to announce the latest addition to our Quill Falcon range… a high-performance dry blasting system. A rapid, reliable and efficient solution for dry blasting projects where speed and performance are critical.

The demand for dry blasting solutions is growing, especially for projects where water is a no-go, such as prepping bridges for repainting. Coatings are improving, but they’re not quite there yet, so dry blasting remains essential. The Supa-Dri dry blasting system is a great new addition to our Quill Falcon blasting range, expanding the types of jobs we can support and helping our customers get more done, faster.

One of the standout features of the Supa-Dri is its high-performance bronze valve filling system, which guarantees a hermetic seal for consistent blasting. The pneumatically controlled main air valve (with a cylinder, not a diaphragm), exhaust valve, and abrasive metering valve work together to deliver a smooth, reliable operation. The pre-set metering valve ensures the optimal amount of abrasive is released – which retains its setting even after decompression.

We’ve also made sure the airline, main air valve, and mixing tube diameters are optimised to reduce pressure loss, and the two-line dead man’s system eliminates the risk of uncontrolled activation. Built to CE regulations, it includes a blast pot emergency stop button for added safety – a must for third-party site work.

Performance-wise, the reliability and efficiency of the Supa-Dri dry blasting system is a real game changer meaning less shutdown time and faster project turnaround time.

We’ve already added five units to our hire fleet, and they’re proving their worth. A recent project undertaken at Smithfield Market, delivered rapid results, leaving us with a very happy contractor and customer. As always, we provide basic training with every hire to ensure safe and effective use.

Get in touch to find out how the Supa-Dri dry blasting system can support your next project or for more details, click here.